Direct fuel injectors, your friend, neighbor, and even the lady that does your hair have complained about them. Chances are, even the CEO of your favorite car company threw a fit when new emission standards forced them to implement direct injection.

Mechanics and enthusiasts everywhere will tell you the current iteration of direct injection is a failure. Some car manufacturers acknowledge the issues that direct injection causes and are mitigating them, but as tinkerers, we love to take our destiny into our own hands. The truth is that GDI is a relatively new tech, and a relative upgrade to the stuff we used to run. However, with new tech come new problems. Today we’ll take a look at direct fuel injector issues and how to troubleshoot them.

What Is Direct Fuel Injection?

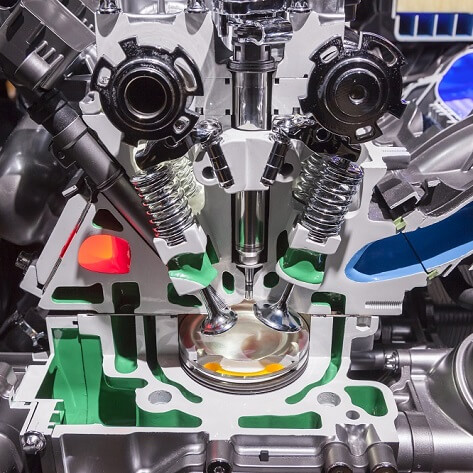

Direct injectors spray fuel straight into the cylinder. The alternative to direct injection is port injection, where the injectors spray fuel into the intake manifold. It mixes with air, and the pressure differential sucks it into the cylinder.

Both have their benefits, but direct injection’s major benefit stems from increased efficiency. As it turns out, GDI systems cause a more complete combustion, thus creating less leftover fuel that gets sucked into the exhaust. Direct injection allows manufacturers to use higher compression ratios and increase boost pressure, which means more power.

An important point to remember is that some engines are dual injection, meaning they use both port injection and direct injection. Engineers opt for such hybrid solutions in an effort to access benefits of both fuel injection systems. We’re talking intake valve cleaning effect of port injection while providing the improved emissions and fuel economy of direct injection.

What Causes Direct Fuel Injectors to Fail?

Of course, the world of direct injection is not all moonshine and roses. Direct injectors are more prone to clogging. GDI engines also suffer from carbon issues, fuel dilution, LSPI (low-speed pre-ignition), and increased chain wear.

Carbon Buildup

This accumulation of carbon, or soot, as it is also known, is a common problem with direct injection engines. There is just less time for the air and fuel to mix before it’s ignited, which leads to a richer fuel-air mixture (more fuel less air).

The pressure difference between the intake and cylinder sucks these leftover deposits back into the air intake, where they collect on the valves.

This issue is also present in port injection cars, but because the fuel sprays onto the valves and cleans them, the buildup of carbon is there, but it’s manageable. Of course, direct-injection cars lack this cleaning effect.

An engine phenomenon called “blow-by” can also cause issues. This is when high pressure in the cylinder causes combustion gasses to leak past the piston rings into the crankcase. Manufacturers solved this issue by using a PCV (positive crankcase ventilation) system which routes the gasses from the crankcase back into the air intake.

However, the PCV system isn’t 100% efficient. The leftover particles that are being routed back into the intake can clog up the PCV system over time. Again, this issue is exacerbated with direct injection cars because there is no valve cleaning, thus resulting in more severe carbon buildup.

So how does any of this affect the injectors? As more and more carbon deposits get reintroduced to combustion chambers, they begin to stick to the injector nozzle. Even without additional carbon buildup invading the injector, the deposits from a fresh combustion cycle are often enough to cause fuel spray issues.

LSPI — Low-Speed Pre-Ignition

Low-speed pre-ignition occurs in your cylinder when the air-fuel mixture is ignited by heat before the spark plug ignites it. A disruption in ignition timing is never good because with it comes increased cylinder pressure, and that can cause catastrophic damage to your engine.

Smaller engines tend to run at higher cylinder pressures at low speed, and this leaves them vulnerable to problems like LSPI. The use of calcium detergents in certain types of engine lubricants also makes LSPI worse.

Installed directly inside the combustion chamber, GDI injector nozzles can suffer all kinds of issues from LSPI. More importantly, a damaged injector can in some instances make the problem even worse.

How to Troubleshoot Direct Fuel Injectors?

Alright, so you’ve noticed that one or more of your cylinders is misfiring. We know that a misfire is caused by issues with one of three main components necessary for a healthy internal combustion cycle — fuel, air, and spark. Let’s say that you’ve narrowed down the issue to fuel delivery. How do you test your GDI injectors?

As it turns out, it’s not as easy as testing regular fuel injectors. Unlike the regular port-mounted injectors, the GDI variety runs on much higher pressure, but also much higher voltage. Where your standard port-mounted injector runs on alternator voltage, which is usually around 14V, a GDI injector can run at 200V or more. That’s why it’s essential to use quality injectors if your factory ones fail. Brands such as Bosch bring quality you can trust. Using cheap GDI injectors is usually asking for trouble.

Troubleshooting these things is made even more difficult by the fact that you may not always get clean access to injector connectors. With all that said, your hands are somewhat tied as far as diagnostic methods go. Here’s what you can do.

OBD II Scan and Live Data

The best way to check modern GDI injectors is to do a comprehensive system scan using a capable OBD II scanner. The reason why we say “capable” is due to the niche nature of the fuel rail/fuel injector live data that is going to be essential for the troubleshooting process.

If your scanner is able to read individual injector faults, you can actually see electrical errors logged for each unit. If not, you should be able to read fuel pressure on the high pressure side of the rail as the engine is working. If you have the expected fuel pressure value on the high-pressure side, you can compare the values right away and see whether you have a leak issue of some sort.

Furthermore, GDI engines generally hold fuel pressure or even show a rise in pressure when you turn the engine off. If your fuel pressure drops the moment you shut the engine off, there’s a chance something is going on with the injectors.

If you’re not finding any errors with the injectors, but your fuel pressure is below optimal, you may have a mechanical injector issue rather than an electrical one.

Digital Storage Oscilloscope

The best way to actually see what’s going on with the injectors is to use a Digital Storage Oscilloscope. Now, this device goes beyond what most people consider DIY friendly, and for a good reason. Things can get confusing once you start measuring the amperage and voltage of GDI injectors.

However, using a DSO will give you the whole picture. You’ll be able to see whether your injectors are opening efficiently, whether they’re holding open and eventually closing. A DSO readout should tell you if you’re dealing with a dead injector, one that is stuck open, or one that is stuck closed. All of these conditions can cause issues.

How to Prevent Direct Fuel Injectors from Being Clogged?

Investing effort to keep your injectors clean is often enough to keep severe carbon buildup at bay. That being said, there are only so many things you can do. The good thing is that most of these preventative measures are easy to perform and don’t necessarily cost a lot of money.

Preventing Crankcase Dilution

Fuel additives are the easiest way to prevent carbon from clogging up your injectors. Additionally, you can pay to get your injectors cleaned, but that’s only necessary if your injectors are obstructed.

The easiest way to prevent fuel from diluting your oil is by taking longer trips. Quick trips to the supermarket tend to not heat engine oil enough to burn off the fuel that is mixed in with it.

You can also warm up your car or let it idle for a period, but the best solution is to take your car on a Sunday drive and open it up on the long road.

Carbon Buildup Prevention In the PCV System

An oil catch can, or oil gasoline separator will reduce carbon buildup in and from the PCV system. Some manufacturers include one, but often the stock catch is of inferior quality due to cost-cutting.

Preventative maintenance is the best maintenance. Buying a good-quality baffled oil catch can save you thousands of dollars in future repairs.

Installation is as easy as attaching the PCV hoses to the oil catch can and mounting it somewhere inside the engine bay. Where you mount the catch can is up to you, but we would suggest mounting it somewhere near the top of the engine bay so that it is accessible.

Preventing LSPI

Engine oil is the most important component in preventing LSPI. If your car is new, and you service it at the dealership, they will usually run Genuine oil provided by your car’s manufacturer. However, if you go to a lube place down the road, there’s no telling what kind of oil they’ll use in your car.

What you’re looking for is less than 7% of oil volatility or evaporation to prevent LSPI.

Now, you can find the technical data on engine oil brands on the websites, but the easy option is just to look out for the ILSAC GF-6 or API SP specification. These specifications will tell you if an engine oil has passed the test for certain issues like LSPI.

Sticking to a high quality lubricant manufacturer such as Motul is a great way to avoid dealing with LSPI altogether. Quality control and advanced manufacturing technologies used by Motul and other tier-one brands prevent LSPI and similar things from ever becoming an issue.

Are GDI Injectors Expensive to Replace?

The short answer is yes. Remember, these operate at much higher pressures and at much higher voltages compared to your port-mounted variety. It only makes sense for them to be more expensive. Now we know that numbers are bouncing in your brain, but it’s unlikely that you will have to replace the injectors, rather than get them cleaned.

Unfortunately, it’s almost a given that you will have to get your valves cleaned at some point if you have direct fuel injectors. The best time to do this is between 40000 and 50000 miles.

Only Use Quality GDI Injectors!

We at eEuroparts.com are always on hand to help! In the event that your direct fuel injectors spontaneously fail, or maybe you’ve realized by this point that you need a baffled oil catch can, we’ve got your back.

You can peruse our catalog to fulfill all your parts needs, from the smallest air filters to forged drivetrain components. You’ll find it all on in our online store. Simply select your car’s year, make, and model, and we’ll give you a complete list of parts that are a guaranteed fit for your vehicle.